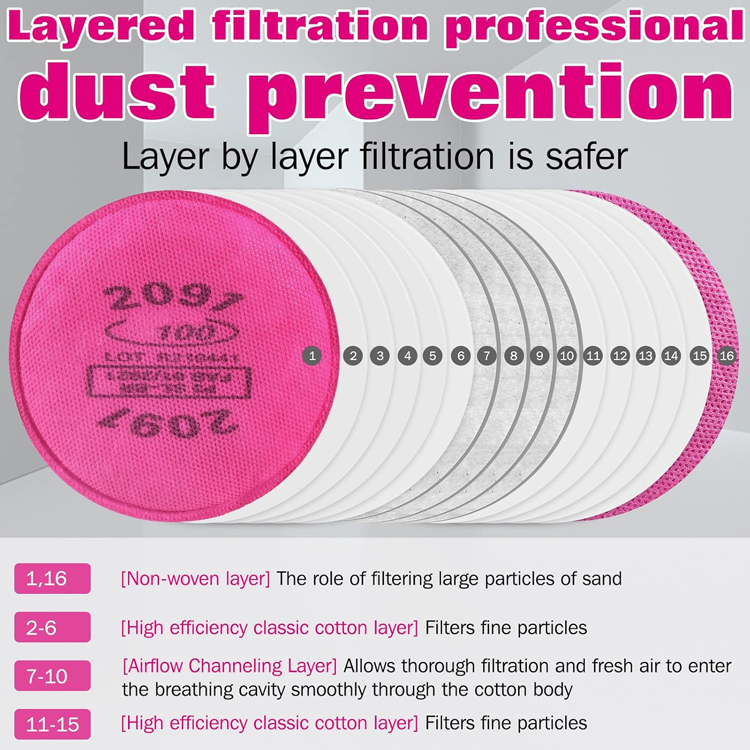

Product Introduction

This machine is the production of manufacturing round respiratory cotton filter equipment, automatic cutting, punching, welding breathing valve onto the plastic frame, ultrasonic welding, cutting and other functions; The filter cotton pad is pre-cut to achieve single conveying, and the filter cotton does not affect the material utilization rate of the conveying structure of the machine but 20% increased compared with the conventional way.

Product Parameters

| Parameter | Value |

|---|

| Speed | 20-30pcs/MIN |

| Output Power | 6KW |

| Power Supply | AC220V 50/60Hz |

| Air Pressure | 0.6-0.8MPa |

| Weight | 1500KG |

| Dimensions | 5670*2274*2251mm |

Applicable incoming material specifications (for reference only):

Item | Gram Weight | Width (mm) | Outer Diameter of Roll Material (mm) | Inner Diameter of Material Tube (mm) | Weight |

Cloth | 25-150 | 130-135 | Φ650 | Φ76.2 | Max 15kg |