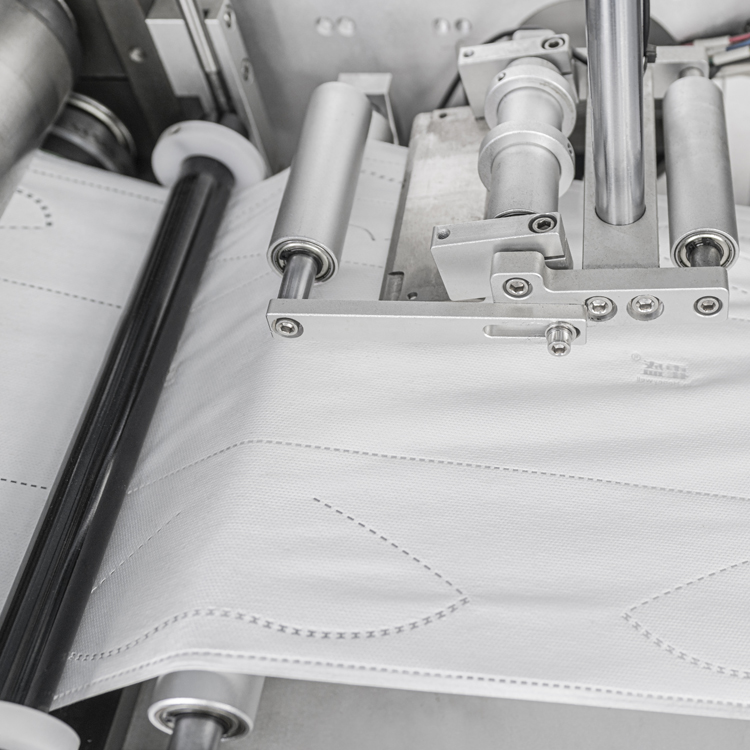

Basic knowledge of ultrasonic equipment maintenance

Source:https://www.sinvta.comDate:2025-10-13

All machines will experience varying degrees of wear during use, and ultrasonic equipment is no exception. So, how should we truly deal with the problem of equipment wear? We should choose suitable lubricants or take appropriate measures to reduce equipment wear. When serious wear occurs, timely maintenance or remedial measures are required to avoid safety accidents.

(I) Types of wear

The phenomenon of continuous loss of surface material during the relative movement of objects in contact with each other is called wear. According to the length of wear extension, it can be divided into two categories: natural wear and accident wear.

The causes of accident wear are caused by the following factors: defective machine structure, poor quality of parts materials, poor manufacturing and processing of parts, incorrect assembly and installation of parts or machines, violation of the machine's safety technical operating procedures and lubrication regulations, poor repair or low repair quality, and other unexpected reasons. In general, when natural wear reaches its limit and is not repaired in time, it is the main cause of accident wear.

(II) Lubrication

1. The role of lubricants

(1) Cooling and heat dissipation. Prevent the parts from heating up due to friction, which may lead to increased adhesive wear and corrosive wear, or even burn out rubber seals or bearings.

(2) Sealing protection. Lubricating grease can effectively isolate moisture, oxygen and harmful media in humid air, and prevent leakage of internal media. Lubricating grease can also prevent water, dust and impurities from invading the friction pair.

(3) Dirt washing function. When the friction pair moves, abrasive particles are generated, and external impurities, dust and sand will aggravate the wear of the friction surface. Forced liquid circulation lubrication can remove the abrasive particles, reducing or avoiding wear.

(4) Reduce friction and wear. Since the lubricating film can reduce the friction factor between the two moving parts, it will reduce the wear and tear of the parts. At the same time, it can also play a damping and vibration absorption role, thereby extending the life of the equipment, reducing power consumption and improving the operating characteristics of the equipment.

2. Types of lubricants

Lubricants can be divided into four categories according to their state: liquid (lubricating oil), semi-solid (grease), solid and gaseous lubricants.

(1) Lubricating oil

Lubricating oil is also called thin oil. Its physical and chemical properties are:

Good fluidity, low freezing point, appropriate viscosity and viscosity coefficient, good load resistance, good oiliness and extrusion resistance, wear resistance; good corrosion resistance and rust resistance; a certain degree of refining; low ash content, carbon residue and acid value; good thermal stability, not easy to volatilize, not easy to ignite, and must have a high ignition point and flash point; good anti-oxidation safety, not easy to age and deteriorate; good water separation and anti-emulsification; must have a certain degree of anti-foaming property.

The following table lists the key points for inspecting the appearance quality of lubricating oil:

Color Change

Deterioration Causes and Prediction

Dirty Oil

Deterioration Causes and Prediction

Darkening of New Oil

Oxidative Degradation

Burning Odor

Heat Degradation

Darkening

Abrasive Particles

Irritating Odor

Degradation of Metal Inert Agent

Turbidity

Water Incorporation

Sedimentation

Foreign Matter

Foaming

Incorporation of Different Oil Types

Lubricant Selection Principles:

a. While ensuring the safe operation of machine friction parts, lubricants with low viscosity should be preferred to reduce energy consumption.

b. Friction parts operating under high speed and load conditions should use low viscosity lubricants, while friction parts operating under low speed and heavy load conditions should use high viscosity lubricants.

c. When the ambient temperature is low, a low viscosity lubricant should be used; when the ambient temperature is low, a high viscosity lubricant should be used. At high temperatures, a lubricant with a high flash point should be used; at low temperatures, a lubricant with a low freezing point should be used.

d. Impact, vibration, reciprocating motion, intermittent motion, etc. are not conducive to the formation of oil film, so lubricating oil with higher viscosity or grease or solid lubricant should be used to ensure reliable lubrication.

e. Lubricating oil with lower viscosity should be used for friction pairs with small clearance, and lubricating oil with lower viscosity should be used for working surfaces with high surface processing accuracy.

f. Lubricating oil with lower viscosity should be used under mechanical circulation conditions, and lubricating oil with slightly higher viscosity should be used for intermittent refueling; lubricating oil with higher viscosity should be used for vertical lubrication surfaces, exposed gears, chains, wire ropes, etc.

g. If there is no suitable brand of lubricating oil, lubricating oil of similar brand can be used as a substitute or mixed. When using as a substitute, only lubricating oil with slightly higher viscosity can be used. When mixing, try not to use two oils with different properties, different brands, or additives.

(2) Grease

Grease, also known as dry oil, is a semi-solid lubricant. It is a plastic lubricant with a colloidal structure made by mixing lubricating liquids such as mineral oil with thickeners.

Principles for selecting grease:

a. Under high-speed and light-load conditions, choose grease with a large needle penetration; under impact, vibration, and intermittent working conditions, choose grease with a small needle penetration.

b. In winter or low-temperature conditions, choose grease prepared with low freezing point and low viscosity oil; in summer or high-temperature conditions, choose grease with a high dropping point.

c. When the fit clearance is large and the surface is rough, choose grease with a small needle penetration; otherwise, choose grease with a large needle penetration.

d. Environmental conditions: Calcium-based grease should generally be used under humid conditions, while sodium-based grease should generally be used under high-temperature conditions.

(3) Solid lubricants

There are many substances that can be used as solid lubricants, including metals, metal compounds, inorganic substances, organic substances, etc. The most commonly used ones are molybdenum disulfide and graphite lubricants.

Molybdenum disulfide lubricant is a lead-gray to black powder with a lustrous sheen. It features excellent lubricity, adhesion, temperature resistance, compressive wear resistance, and resistance to oxidation and chemical corrosion. It provides excellent lubrication for equipment operating under high-speed, high-temperature, high-load, low-temperature, and chemically corrosive conditions.

Currently, molybdenum disulfide lubricants are available in powder, aqueous, oil, ointment, grease, crayon, and other solid film-forming formulations. Equipment lubrication adheres to the "five requirements": fixed location, fixed quality, fixed quantity, fixed schedule, and fixed personnel. Lubricant quality monitoring technology is used: select key equipment and equipment with high oil consumption, and determine oil quality test parameters such as kinematic viscosity, moisture content, acid value, water-soluble acids and bases, and mechanical impurities to determine optimal lubrication.

Recommended News

-

Exhibition Invitation | Huitong Automation cordially invites you to SINCE 2025 (The 21st Shanghai International Nonwoven Materials Exhibition)

The 21st Shanghai International Nonwoven Materials Exhibition (SINCE2025), a biennial professional exhibition for the nonwoven materials industry.Exhibition Dates: December 3-5, 2025Exhibition Venue: Shanghai World Expo Exhibition & Convention Center, No. 850 Bocheng Road, Pudong New Area, Shanghai, ChinaHall Number: Hall 1Booth Number: 1H20**SINCE 2025:** Don't Miss Out!Top Exhibitors: 300+ renowned companies, providing a one-stop shop for innovative achievements across the entire nonwoven materials chain!Cutting-Edge Insights at the Forum: The SINCE2025 Nonwoven Materials Innovation and Development Forum will be held concurrently. Invited industry leaders, experts, and scholars will provide in-depth analysis and trend predictions on hot topics, helping you grasp market trends and

2025-11-21 08:31:21 -

Leading a new chapter in respiratory protection! HuiTong appears at A+A 2025, exploring the future of respiratory protection automation

From November 4th to 7th, 2025, the 39th International Occupational Safety and Health Exhibition (A+A 2025), a leading global event in the field of occupational safety and health, will grandly open at the Düsseldorf Exhibition Center (Stockumer Kirchstraße 61, 40474 Düsseldorf, Germany). Huitong

2025-10-21 16:20:10 -

Basic knowledge of ultrasonic equipment maintenance

All machines will experience varying degrees of wear during use, and ultrasonic equipment is no exception. So, how should we truly deal with the problem of equipment wear? We should choose suitable lubricants or take appropriate measures to reduce equipment wear. When serious wear occurs, timely maintenance or remedial measures are required to avoid safety accidents.(I) Types of wearThe phenomenon of continuous loss of surface material during the relative movement of objects in contact with each other is called wear. According to the length of wear extension, it can be divided into two categories: natural wear and accident wear.The causes of accident wear are caused by the following factors: defective machine structure, poor quality of parts materials, poor manufacturing and processing of

2025-10-13 14:17:58 -

The Evolution of Surgical Gowns: From Cotton to Smart Manufacturing: A Medical Revolution

In the operating room, a seemingly ordinary surgical gown carries not only the doctor's responsibility but also a century-long history of medical technological evolution. From the initial repeatedly starched cotton cloth to today's fully automated disposable non-woven fabric, the evolution of surgical gown materials reflects not only technological progress but also humanity's determination to fight infection and protect lives.First Generation: The Cotton Era—The Risks of ReuseIn the early 20th century, surgical gowns were mostly made of cotton. This natural fiber is moisture-wicking and breathable, but it harbors a fatal flaw: cotton fibers loosen after repeated washing, making them highly susceptible to bacteria and bodily fluids. To make matters worse, sterilization technolo

2025-10-10 08:02:41