Daily and efficient production of disposable non-woven bandana caps

Source:https://www.sinvta.comDate:2025-10-08

Have you ever seen one? In hospitals, food factories, beauty salons, and even in your own kitchen, there's a discreet presence: the disposable non-woven bandana cap. It doesn't steal the show, it doesn't sparkle, but without it, many tasks become less reassuring.

It's used in more ways than you can imagine.

In hospitals, it's the "ticket" to the operating room, preventing even a tiny hair from transmitting bacteria. In food processing plants, it's an "invisible safety guard," protecting every piece of cake and every bottle of drink. In beauty salons, it's a "hair guard," preventing perms and dyeing solutions from getting on the forehead and neck. In electronics factories and laboratories, it's a "silent shield," blocking tiny dust particles. Some families even wear it while doing housework or baking—simple, clean, and reassuring. In short: it's everywhere you can imagine and even beyond.

Why does everyone love it?

Disposable non-woven bandage caps are lightweight and breathable, ensuring they stay comfortable even after extended wear. The elastic band fits all head shapes and can be discarded after use, eliminating the need for cleaning and reducing the risk of cross-infection. Most importantly, they're affordable and convenient, making bulk purchases a breeze.

Deceptively simple, the demand is astonishing.

You might be surprised to learn that a medium-sized hospital or a large food factory can use thousands to tens of thousands of these caps daily. This high market demand demands fast and stable production. However, using manual or semi-automatic machines is not only slow but also prone to inconsistent quality—caps with varying tightness and loose welds—which directly impacts the customer experience.

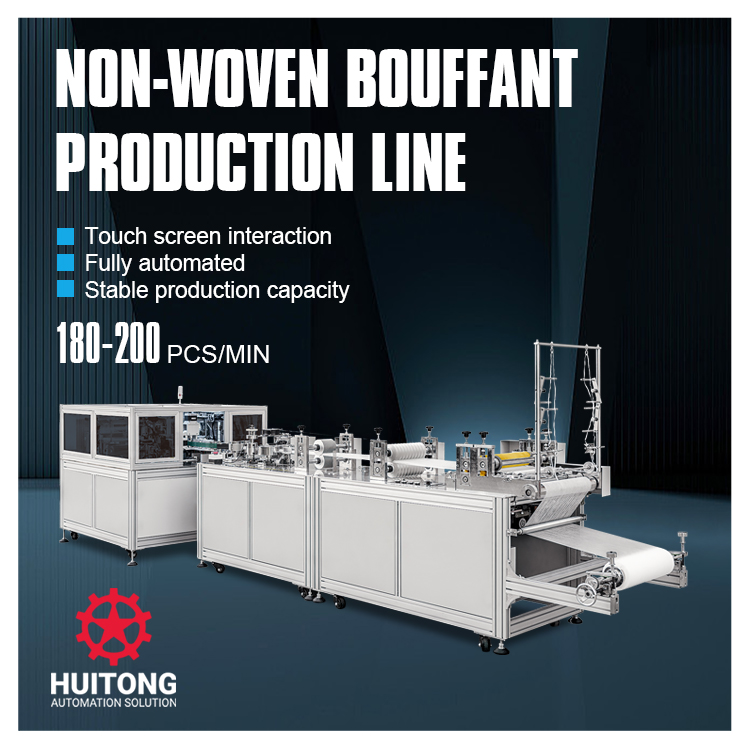

Huitong Automation's Efficient Solutions

Huitong Automation's fully automatic disposable non-woven bandana cap manufacturing machine is designed to address these pain points: Highly Fast: 200-260 caps can be produced per minute, easily producing over a million caps per day. Fully Automatic: From coiling to folding, welding, and collection, the entire process requires no human intervention.

Sturdy and Comfortable: Ultrasonic welding technology ensures a sturdy, non-binding cap. Stable and Durable: PLC intelligent control system ensures smooth, continuous operation. Cost-Effective and Worry-Free: Labor costs and scrap rates are both reduced.

This not only doubles the factory's production efficiency but also enables the product to be exported overseas, establishing a strong foothold in the international market. Disposable non-woven bandana caps may be a small consumable, but they represent a significant market demand for hygiene and safety. The addition of automation has transformed this "small item" into a "big business."

Recommended News

-

Exhibition Invitation | Huitong Automation cordially invites you to SINCE 2025 (The 21st Shanghai International Nonwoven Materials Exhibition)

The 21st Shanghai International Nonwoven Materials Exhibition (SINCE2025), a biennial professional exhibition for the nonwoven materials industry.Exhibition Dates: December 3-5, 2025Exhibition Venue: Shanghai World Expo Exhibition & Convention Center, No. 850 Bocheng Road, Pudong New Area, Shanghai, ChinaHall Number: Hall 1Booth Number: 1H20**SINCE 2025:** Don't Miss Out!Top Exhibitors: 300+ renowned companies, providing a one-stop shop for innovative achievements across the entire nonwoven materials chain!Cutting-Edge Insights at the Forum: The SINCE2025 Nonwoven Materials Innovation and Development Forum will be held concurrently. Invited industry leaders, experts, and scholars will provide in-depth analysis and trend predictions on hot topics, helping you grasp market trends and

2025-11-21 08:31:21 -

Leading a new chapter in respiratory protection! HuiTong appears at A+A 2025, exploring the future of respiratory protection automation

From November 4th to 7th, 2025, the 39th International Occupational Safety and Health Exhibition (A+A 2025), a leading global event in the field of occupational safety and health, will grandly open at the Düsseldorf Exhibition Center (Stockumer Kirchstraße 61, 40474 Düsseldorf, Germany). Huitong

2025-10-21 16:20:10 -

Basic knowledge of ultrasonic equipment maintenance

All machines will experience varying degrees of wear during use, and ultrasonic equipment is no exception. So, how should we truly deal with the problem of equipment wear? We should choose suitable lubricants or take appropriate measures to reduce equipment wear. When serious wear occurs, timely maintenance or remedial measures are required to avoid safety accidents.(I) Types of wearThe phenomenon of continuous loss of surface material during the relative movement of objects in contact with each other is called wear. According to the length of wear extension, it can be divided into two categories: natural wear and accident wear.The causes of accident wear are caused by the following factors: defective machine structure, poor quality of parts materials, poor manufacturing and processing of

2025-10-13 14:17:58 -

The Evolution of Surgical Gowns: From Cotton to Smart Manufacturing: A Medical Revolution

In the operating room, a seemingly ordinary surgical gown carries not only the doctor's responsibility but also a century-long history of medical technological evolution. From the initial repeatedly starched cotton cloth to today's fully automated disposable non-woven fabric, the evolution of surgical gown materials reflects not only technological progress but also humanity's determination to fight infection and protect lives.First Generation: The Cotton Era—The Risks of ReuseIn the early 20th century, surgical gowns were mostly made of cotton. This natural fiber is moisture-wicking and breathable, but it harbors a fatal flaw: cotton fibers loosen after repeated washing, making them highly susceptible to bacteria and bodily fluids. To make matters worse, sterilization technolo

2025-10-10 08:02:41