How to choose a reliable automation equipment? Here is a guide to avoid pitfalls!

Source:https://www.sinvta.comDate:2025-10-08

With the increasing prevalence of automated equipment, purchasing equipment has become the first step for many factory owners to transform and upgrade. However, with so many options on the market and all the hype surrounding them, how can you choose reliable, stable, and cost-effective automation equipment? This guide to avoiding pitfalls is for everyone involved in equipment selection.

1. Choosing the right equipment doesn't mean buying expensive equipment; the key is to find the right equipment for you.

Many people fall into this trap early on: blindly pursuing high-spec equipment and high production capacity, but ultimately failing to meet their needs.

Tips for avoiding pitfalls:

First, clarify your needs: product specifications, production requirements, budget, and whether automated packaging is required.

Make a list of requirements and prioritize equipment with the right production capacity and features.

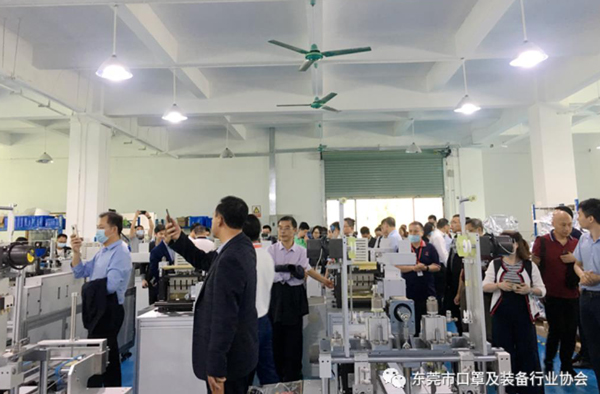

2. The manufacturer's technical strength must be "visible." Advertising alone isn't enough; truly reliable equipment manufacturers will offer in-person visits, online demonstrations, or showcase real customer cases.

Tips for avoiding pitfalls:

Visit the factory's production line and check whether it's in-house developed or OEM-branded.

Pay attention to details: Is the equipment structure sound? Is it CE-certified? Is after-sales service prompt?

Request customer use case videos or live operation videos.

We often host on-site customer trials, where a single machine can run nonstop for a full day. Customers are most concerned about instability after purchase, so we let them see the actual performance in advance.

3. Don't be blindly attracted by the term "fully automatic."

Many promotions these days emphasize "fully automatic," but is it truly so? Does manual loading and unloading, sorting, and packaging still require work?

Tips for avoiding pitfalls:

Ask clearly: In which specific steps does the degree of automation manifest?

Understand how many people are required to operate the machine? Does it truly save labor?

Can it be upgraded? Does it support modular expansion or mold replacement?

One customer previously purchased so-called "fully automatic" equipment, but it still required two people to unload the machine. Later, they switched to one of our machines with automatic stacking, which cut the labor requirements in half.

4. Reasonable pricing is key to long-term business.

Price is certainly important, but the saying "cheap goods are cheap" is true in the automation equipment industry. The money you save can be worth ten times more in subsequent repairs, downtime, and low yield rates. Tips for avoiding pitfalls:

Don't just look at the quote; consider the overall cost (labor savings, consumables savings, after-sales service, and service life).

Choose a manufacturer with a professional after-sales team who can respond quickly to equipment issues.

Clearly include after-sales service details in the contract (warranty period, on-site service, replacement cycle, etc.).

We offer video tutorials, remote support, on-site training, a one-year warranty, and lifetime maintenance, ensuring not only affordable purchases but also long-lasting, smooth operation.

V. Choosing equipment isn't just about buying a machine; it's about choosing a reliable partner.

Automation isn't a one-time deal. A truly excellent equipment manufacturer will work with you to solve problems, optimize processes, and build production lines.

✅ The right approach:

Check whether there are long-term repeat customers.

Whether you can customize product functions and molds.

Whether you prioritize the after-sales experience and avoid perfunctory or evasive handling.

One customer, in their sixth year with us, started with a single piece of equipment and then customized a full line. He said, "I chose you not only because of the quality of your equipment, but also because you never push us aside when problems arise."

Recommended News

-

Exhibition Invitation | Huitong Automation cordially invites you to SINCE 2025 (The 21st Shanghai International Nonwoven Materials Exhibition)

The 21st Shanghai International Nonwoven Materials Exhibition (SINCE2025), a biennial professional exhibition for the nonwoven materials industry.Exhibition Dates: December 3-5, 2025Exhibition Venue: Shanghai World Expo Exhibition & Convention Center, No. 850 Bocheng Road, Pudong New Area, Shanghai, ChinaHall Number: Hall 1Booth Number: 1H20**SINCE 2025:** Don't Miss Out!Top Exhibitors: 300+ renowned companies, providing a one-stop shop for innovative achievements across the entire nonwoven materials chain!Cutting-Edge Insights at the Forum: The SINCE2025 Nonwoven Materials Innovation and Development Forum will be held concurrently. Invited industry leaders, experts, and scholars will provide in-depth analysis and trend predictions on hot topics, helping you grasp market trends and

2025-11-21 08:31:21 -

Leading a new chapter in respiratory protection! HuiTong appears at A+A 2025, exploring the future of respiratory protection automation

From November 4th to 7th, 2025, the 39th International Occupational Safety and Health Exhibition (A+A 2025), a leading global event in the field of occupational safety and health, will grandly open at the Düsseldorf Exhibition Center (Stockumer Kirchstraße 61, 40474 Düsseldorf, Germany). Huitong

2025-10-21 16:20:10 -

Basic knowledge of ultrasonic equipment maintenance

All machines will experience varying degrees of wear during use, and ultrasonic equipment is no exception. So, how should we truly deal with the problem of equipment wear? We should choose suitable lubricants or take appropriate measures to reduce equipment wear. When serious wear occurs, timely maintenance or remedial measures are required to avoid safety accidents.(I) Types of wearThe phenomenon of continuous loss of surface material during the relative movement of objects in contact with each other is called wear. According to the length of wear extension, it can be divided into two categories: natural wear and accident wear.The causes of accident wear are caused by the following factors: defective machine structure, poor quality of parts materials, poor manufacturing and processing of

2025-10-13 14:17:58 -

The Evolution of Surgical Gowns: From Cotton to Smart Manufacturing: A Medical Revolution

In the operating room, a seemingly ordinary surgical gown carries not only the doctor's responsibility but also a century-long history of medical technological evolution. From the initial repeatedly starched cotton cloth to today's fully automated disposable non-woven fabric, the evolution of surgical gown materials reflects not only technological progress but also humanity's determination to fight infection and protect lives.First Generation: The Cotton Era—The Risks of ReuseIn the early 20th century, surgical gowns were mostly made of cotton. This natural fiber is moisture-wicking and breathable, but it harbors a fatal flaw: cotton fibers loosen after repeated washing, making them highly susceptible to bacteria and bodily fluids. To make matters worse, sterilization technolo

2025-10-10 08:02:41