Product Introduction

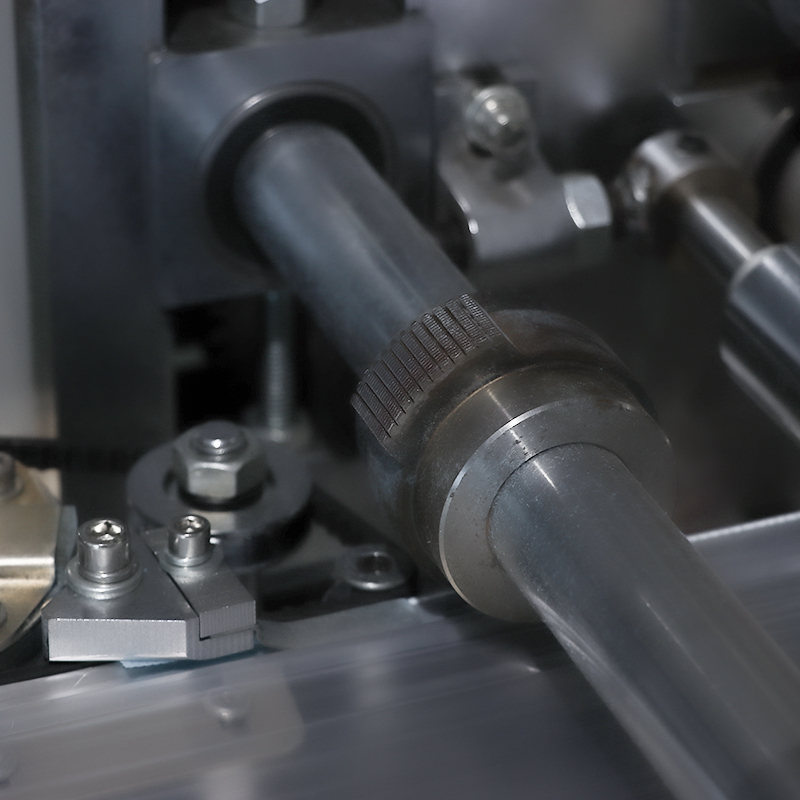

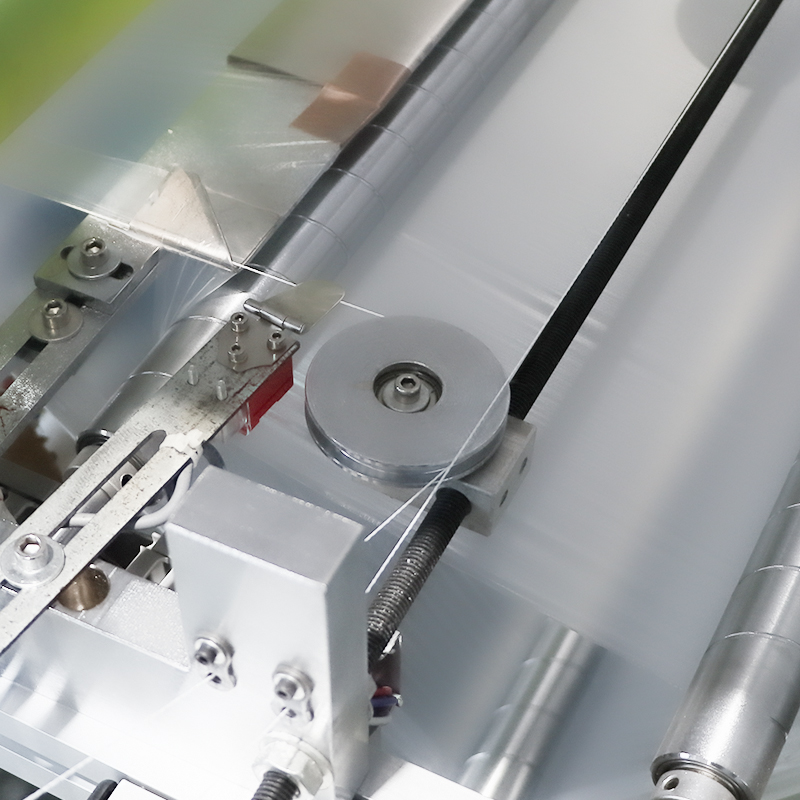

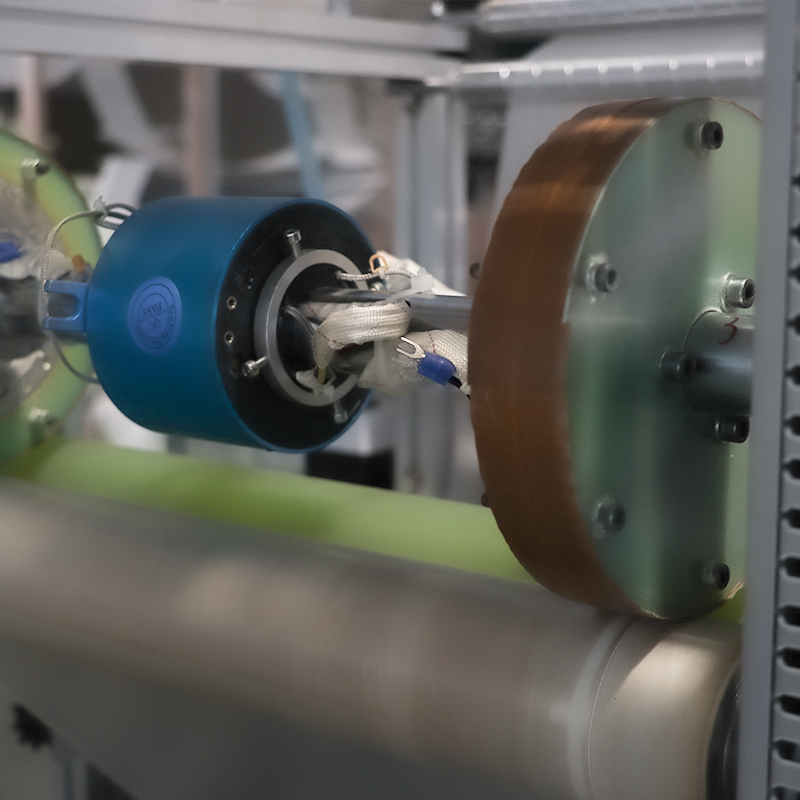

This machine uses ultrasonic technology for fully automatic control. It utilizes ultrasonic welding technology to effectively secure the ends of the elastic sleeve, completing the entire process from raw material feeding to finished product in one go. It is widely used in production lines, hospitals, cleanrooms, food processing, and other industries, including plants and household cleaning products. You can choose the appropriate model based on your non-woven fabric needs.

Configuration List (For reference only)

{content:ext_Configuration}